PRODUCT INTRODUCTION

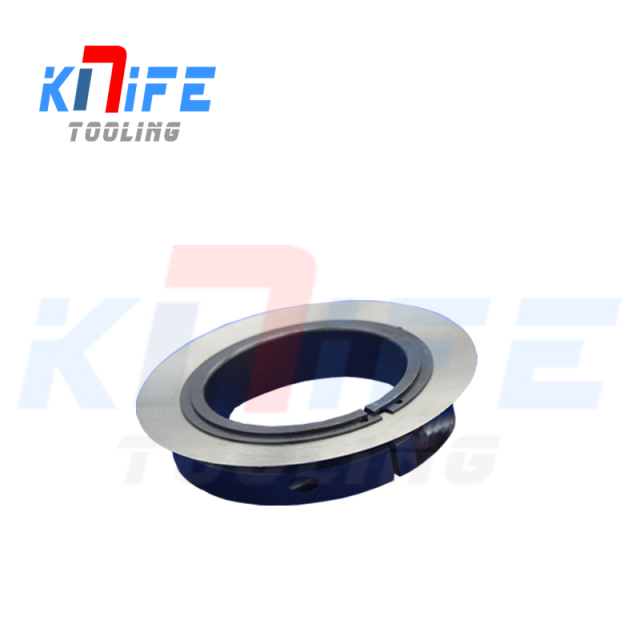

Splitting knives are mainly used for slitting paper, film, gold foil, silver foil, aluminium foil,tape....etc. Usually it contains top dish knife, bottom knife, knife holder, spring, snap ring, and pin. It requires the blades with less resistance, and more wear-resistance. In order to meet the increasing requirements on tolerance, even μm some times, we will choose 9CrSi, D2, HSS, Tungsten carbide....etc.

| Chart of Standard Bottom knife |

| Specification |

Outer Diameter |

Inner Diameter |

Width |

Thickness |

Keyway Width |

Keyway Depth |

Blade Angle |

| φ62*φ42*1 |

62 |

42 |

2 |

1 |

2.2 |

45 |

45° |

| φ62*φ42*1.5 |

62 |

42 |

2.5 |

1.5 |

2.2 |

44.5 |

45° |

| φ64*φ40*1 |

64 |

40 |

1.8 |

1 |

3 |

44 |

45° |

| φ75*φ45*1 |

75 |

45 |

2 |

1 |

3 |

49 |

45° |

| φ75*φ45*1.5 |

75 |

45 |

2.5 |

1.5 |

2.2 |

49 |

45° |

| φ100*φ75*1 |

100 |

75 |

2.3 |

1 |

2.2 |

77.6 |

45° |

| φ105*φ70*1 |

105 |

10 |

2 |

1 |

3.2 |

75 |

45° |

| φ105*φ70*1.5 |

105 |

70 |

2.5 |

1.5 |

3.2 |

75 |

45° |

| φ140*φ95*1 |

105 |

95 |

2 |

1 |

3.2 |

100 |

45° |

| Chart of Standard Bottom knife |

| Specification |

Outer Diameter |

Inner Diameter |

Width |

Blade Width |

Large-Medium Diameter |

Small-Medium Diameter |

Keyway Width |

Keyway Depth |

| φ70*φ45*8/10 |

70 |

45 |

10 |

8 |

67 |

59 |

10 |

49 |

| φ70*φ45*2.5/4 |

70 |

45 |

4 |

2.5 |

67 |

59 |

10 |

49 |

| φ80*φ50*3.5/5 |

80 |

50 |

5 |

3.5 |

77 |

65 |

10 |

53.8 |

| φ80*φ50*8/10 |

80 |

50 |

10 |

8 |

77 |

65 |

10 |

53.8 |

| φ80*φ50*8/10 |

80 |

60 |

10 |

8 |

77 |

69 |

- |

- |

| φ70*φ45*4/6 |

70 |

45 |

6 |

4 |

67 |

59 |

- |

- |

| φ108*φ80*8/10 |

108 |

80 |

10 |

8 |

105 |

90 |

- |

- |

| φ108*φ80*18/20 |

108 |

80 |

20 |

18 |

104 |

90 |

- |

- |

WHY CHOOSE US?

07

Professional after-sales team

ABOUT US

Knifetooling Machinery Technology is located in Bowang Town which is one of the most famous town for blades in China. The company has been committed to providing knives and blades of high productivity and high precision. From raw material, heat treatment to finishing, Knifetooling keeps track and exercises strict control over every piece, in order to improve the performance of our products and production efficiency, at the same time reduce the production cost. By working with counterparts from western countries closely, Knifetooling continues to innovate and pursues the better quality. Besides standard raw materials like 9CrSi, D2, H13, the company also has its own special materials which are specializing in processing high tensile strength metal coils. Material-choosing, cutting performance improvement, professional advices are available here. Good material, skilled producing process and responsible after-sale service make our products popular at home and abroad.

SHIPPING

As a leading company of industrial blades, we have cooperated with many first class forwarder all over the world, no matter you want to ship it by air or sea. Besides, in order to meet the urgent requirements of some customers, we have cooperated with some agents of courier, like DHL, Fedex, UPS, TNT.

FAQ

How can i get the goods, because it is my first time to import

We can provide DDP or DDU for some customers who purchases first time. Besides, we have some local agent in your country.

I want to place a trail order, can i pay not through company accounting?

Yes, we can accept Paypal, Western Union, Trade Assurance....etc.

How long is your production time?

Usually, it takes 45 days for most goods. If it is standard, we can send it within 5-7 days.

I have no drawing, but dimension and photos only. How can i know your products is suitable to us?

We will make production drawing according to your photos before we produce. In addition, we can make production drawing according to your sample.

How is your payment term?

Usually, we will collect 100% if the total amount is less, because we hope we can reduce the banking cost for both sides. If the total amount is more, we will collect 30% and 70%. In addition, we can accept Letter of Credit.